If you need any help, please feel free to contact us

Antistatic consumables are a series of products used to reduce the generation and accumulation of static electricity, and they are widely used in electronic manufacturing, medical equipment, aerospace, and other industries. These consumables include ESD protective clothing, ESD gloves, and ESD packaging materials to protect sensitive devices from electrostatic damage. The use of these consumables can improve production efficiency and reduce failures and losses caused by static electricity.

This is a critical question regarding health and safety. While many people are accustomed to using cotton swabs to clean their ear canals, not all cot...

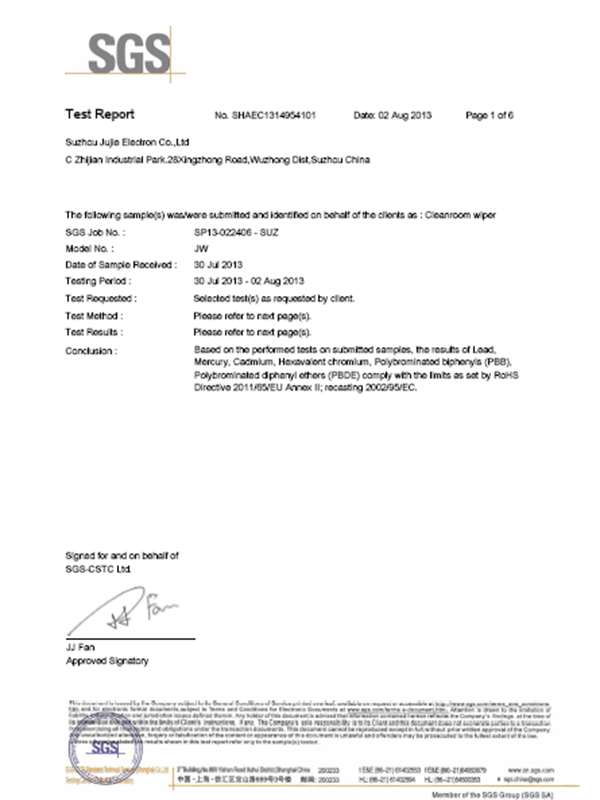

View MoreBasic Properties of Nonwoven Wipes As a polymer material product, Nonwoven Wipes' basic properties determine their advantages in the cleaning process:...

View MoreIn ISO 5/6 standard cleanroom environments, Clean Swabs are a key tool for ensuring dust-free and fiber-free products. 1. No Fiber Shedding Clean Swab...

View MoreBest Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

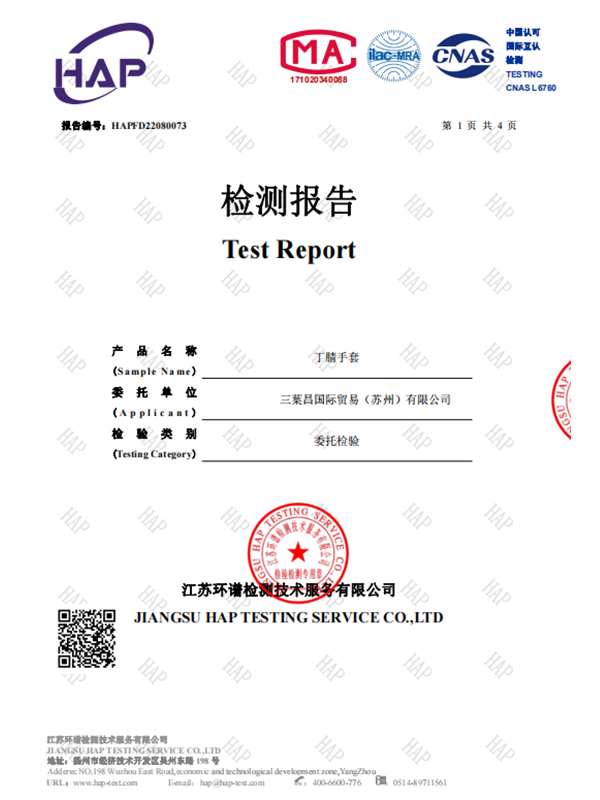

View MoreWhat are the common types of Antistatic gloves?

Suzhou Jujie Electron Co., Ltd' antistatic gloves cover a wide range of needs. The core types and features are as follows:

PVC gloves

Material Characteristics: Made from polyvinyl chloride, they offer both Antistatic and water-resistant properties, with a smooth surface that resists dust absorption.

Applications: Suitable for electronic assembly, semiconductor testing, and other processes requiring gentle handling of sensitive components to avoid the risk of electrostatic breakdown.

Nitrile gloves

Material Characteristics: Made from nitrile rubber, they are oil- and chemical-resistant, with excellent elasticity and a snug fit.

Applications: Suitable for precision electronic soldering, chip packaging, and other applications to prevent hand sweat or oil from contaminating sensitive components.

Antistatic spark gloves

Design Logic: Conductive fibers are embedded in the glove surface, creating an "embossed" texture that enhances friction for easier handling while also dissipating static electricity.

Applications: Electronics manufacturing processes that require frequent handling of small components, such as resistors and capacitors, require both Antistatic protection and ease of use. Other variants

For example, Antistatic PU gloves, made of polyurethane, are lighter, thinner, and more breathable. Antistatic knitted gloves, with a cotton base and conductive yarn, are suitable for long-duration work and meet the diverse comfort and protection needs of different industries.

How do Antistatic consumables reduce the risk of electrostatic damage in the electronics manufacturing industry?

In electronics manufacturing, electrostatic discharge (ESD) can cause chip burns and circuit shorts. Suzhou Jujie Electron Co., Ltd' Antistatic consumables reduce this risk through "full-process protection":

Personnel protection: Blocking the source of static electricity

Antistatic gloves, protective clothing, and other consumables use conductive fibers to conduct static electricity from the human body to the ground, preventing static electricity accumulation during operation. For example, workers wearing nitrile gloves while soldering circuit boards can prevent static electricity from penetrating the chips.

Equipment protection: Isolating sensitive components

Antistatic packaging materials, such as Antistatic bubble bags and shielding bags, create an "electrostatic barrier" during component storage and transportation, preventing static electricity from entering. Suzhou Jujie Electron Co., Ltd' Antistatic bags utilize metalized film, achieving a shielding effectiveness of over 99%. Environmental Protection: Building an ESD Suppression System

Antistatic flooring, ionizing fans, and other consumables work together to reduce static electricity concentrations in production workshops. For example, Antistatic flooring in cleanrooms can quickly dissipate static electricity, while working with ionizing fans to neutralize airborne static electricity, mitigating static hazards at the source.

Process Protection: Standardizing Operating Standards

Suzhou Jujie Electron Co., Ltd provides integrated "Antistatic consumables + training" services, guiding companies to establish ESD management processes, such as wearing gloves and using Antistatic packaging, to systematically reduce the likelihood of electrostatic damage.

How does Suzhou Jujie Electron Co., Ltd' cleanroom production line ensure the quality of Antistatic consumables?

Suzhou Jujie Electron Co., Ltd' cleanroom production line is the core guarantee of the quality of Antistatic consumables. Its technological advantages are reflected in:

High-standard clean environment

The cleanroom is built to ISO Class 5 and ISO Class 6 standards and is NEBB-certified, with air cleanliness far exceeding industry standards. For example, an ISO Class 5 cleanroom has a particle count of ≤100 particles ≥0.5μm per cubic meter of air, completely eliminating dust contamination during the production process. Fully Automated Production Equipment

Equipped with 48 fully automated weaving, washing, and shaping production lines, as well as imported laser cutting and ultrasonic cutting machines from Japan. For example, the laser cutting machine enables precise cutting of Antistatic gloves with an accuracy of ≤0.1mm, ensuring consistent product dimensions. The ultrasonic cutting machine eliminates the burrs often associated with traditional cutting, enhancing both product appearance and protective performance.

High-end Testing Equipment

Infrared spectrometers and liquid particle counters imported from Germany, the United States, and South Korea are used to comprehensively test the conductivity, wear resistance, and cleanliness of Antistatic consumables. For example, the infrared spectrometer analyzes the molecular structure of the glove material to ensure uniform distribution of Antistatic fibers. The liquid particle counter measures cleanliness after washing to prevent residual impurities that may affect product performance.

Dual Improvement in Production Capacity and Quality

Large-scale production in the 33,000 square meter facility, combined with a tenfold increase in production capacity, ensures efficient order delivery while reducing quality fluctuations through standardized processes. For example, the fully automated production line reduces manual intervention, stabilizing the resistance of Antistatic gloves at 10⁶ - 10⁹Ω, ensuring consistent performance for each batch of products.