If you need any help, please feel free to contact us

A cleaning Q-tip is a disposable tool used for cleaning and disinfecting, usually consisting of a cotton tip and a plastic or wooden pole. They are widely used in medical, laboratory, electronic equipment cleaning, and other fields to remove dust, dirt, and bacteria. The tip of a cleaning cotton swab is usually specially treated to ensure that no fiber residue is left behind while maintaining sufficient cleaning power.

This is a critical question regarding health and safety. While many people are accustomed to using cotton swabs to clean their ear canals, not all cot...

View MoreBasic Properties of Nonwoven Wipes As a polymer material product, Nonwoven Wipes' basic properties determine their advantages in the cleaning process:...

View MoreIn ISO 5/6 standard cleanroom environments, Clean Swabs are a key tool for ensuring dust-free and fiber-free products. 1. No Fiber Shedding Clean Swab...

View MoreBest Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreHow does the "no fiber residue" feature of a cleaning cotton swab affect cleaning performance?

Suzhou Jujie Electron Co., Ltd., a professional manufacturer of clean cotton swabs, prioritizes "no fiber residue" as its core advantage. This impact on cleaning performance is reflected in the following key dimensions:

Avoiding secondary contamination: Ordinary cotton swabs easily shed fibers, which can become a new source of contamination (e.g., between electronic components and on medical device surfaces). Suzhou Jujie's Clean Swab uses a special process to treat the swab tip to ensure no fiber residue after cleaning, completely eliminating the "clean-contamination cycle."

Protecting delicate surfaces: When cleaning electronic devices or optical instruments, fiber residue can scratch the surface or affect signal transmission. Suzhou Jujie's Clean Swab's fiber-free feature allows for safe cleaning of delicate components, extending the life of the equipment.

Improving cleaning efficiency: No fiber residue means no repeated cleaning, allowing dust and dirt to be removed in a single operation. This makes it particularly suitable for applications requiring high cleaning efficiency, such as laboratories and medical facilities.

What applications are different types of cleaning cotton swabs suitable for?

Suzhou Jujie Electronics Co., Ltd. has developed a variety of Clean Swab products for different scenarios. The following are typical types and their applications:

Foam Swabs:

Electronic Device Cleaning: The foam material is soft and highly absorbent, making it suitable for cleaning mobile phone screens, keyboard crevices, and other areas, avoiding scratches while effectively removing oil stains.

Print Head Maintenance: Print Head Foam Swabs are designed specifically for printer printheads, accurately removing ink residue and restoring print accuracy.

General Laboratory Cleaning: Foam swabs are static-free and fiber-free, making them suitable for removing dust from laboratory instrument surfaces while avoiding static electricity.

Polyester Swabs:

Precision Electronic Component Cleaning: The polyester tip has a moderate hardness, making it suitable for cleaning circuit board solder joints, chip crevices, and other areas without damaging component structures.

Post-Sterilization Cleaning of Medical Devices: The polyester tip is chemical-resistant and can be used to clean surgical instruments after sterilization, ensuring no residue or corrosion.

Optical Instrument Maintenance: Polyester swabs are glare-free and suitable for cleaning microscope lenses, camera sensors, and other areas, maintaining optical clarity.

How does Suzhou Jujie Electronics Co., Ltd. ensure product quality?

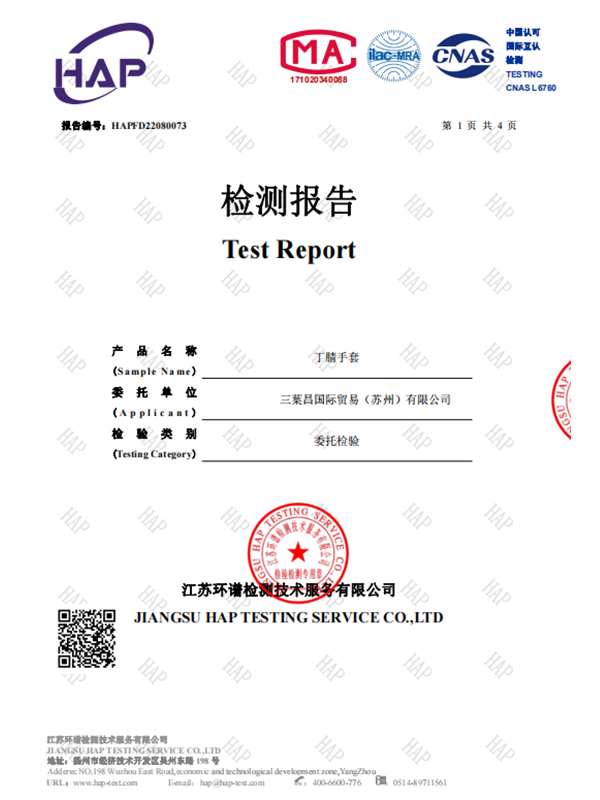

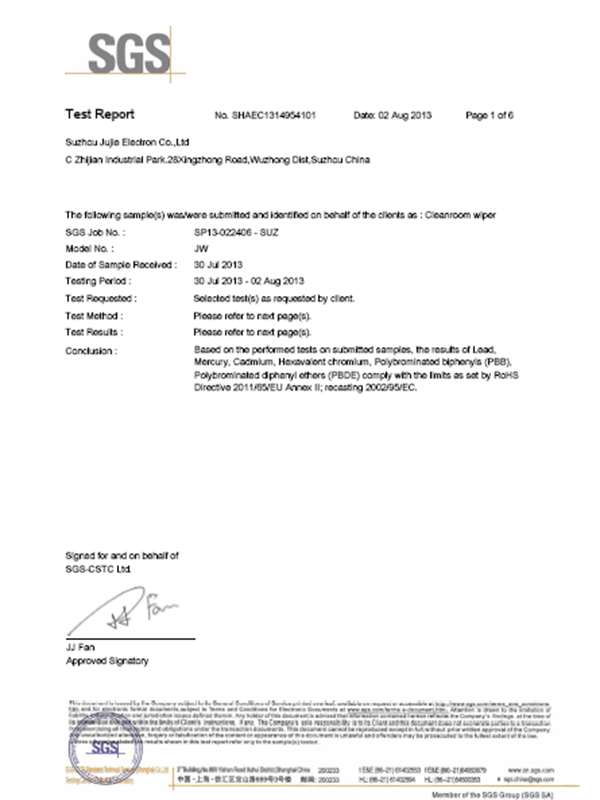

As a high-tech enterprise, Suzhou Jujie Electron Co., Ltd. ensures the quality of its Clean Swab products through comprehensive process control:

High-standard clean production environment:

The company boasts ISO Class 5 and 6 cleanrooms (NEBB certified) and a lint-free workshop covering 8,000 square meters. This cleanroom environment strictly controls particulate matter and microorganisms, preventing product contamination at the source and ensuring that Clean Swab meets the high-purity requirements of medical and electronics applications.

Advanced automated production and testing equipment:

On the production side, 48 new automated weaving, washing, and shaping production lines have been added, equipped with laser and ultrasonic cutting machines imported from Japan to achieve precise shaping of cotton swab tips, eliminating the risk of fiber residue.

On the testing side, infrared spectrometers and liquid particle counters imported from Germany, the United States, and South Korea are equipped to comprehensively test each batch of products for composition, cleanliness, and strength to ensure consistency.

Full-process quality control system:

From raw material selection (such as medical-grade cotton and antistatic plastic rods) to production, packaging, and warehousing, each step is governed by a standardized SOP (Standard Operating Procedure). For example, cotton swab tips undergo a three-step process: pre-cleaning, special treatment, and residue testing to ensure no fiber shedding. Finished products must pass sterility testing, strength testing, and compatibility verification before they can be shipped.

Technical Team and Continuous Innovation:

The company has focused on the research and development of cleanroom and anti-static products for 15 years. The technical team continuously optimizes the material formulation and process of Clean Swab (such as improving the liquid absorption of foam cotton swabs and the anti-static coating of polyester tips) to ensure that the products always meet the evolving needs of industries such as medical, electronics, and laboratories.