If you need any help, please feel free to contact us

This is a critical question regarding health and safety. While many people are accustomed to using cotton swabs to clean their ear canals, not all cot...

View MoreBasic Properties of Nonwoven Wipes As a polymer material product, Nonwoven Wipes' basic properties determine their advantages in the cleaning process:...

View MoreIn ISO 5/6 standard cleanroom environments, Clean Swabs are a key tool for ensuring dust-free and fiber-free products. 1. No Fiber Shedding Clean Swab...

View MoreBest Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreHow do consumables differ across different scenarios?

The core differences in cleanroom consumables stem from the cleanliness requirements, contaminant types, and operating frequency of the application. Suzhou Jujie Electron Co., Ltd. offers customized designs for different scenarios.

Typical differences are as follows:

1. Semiconductor/Optoelectronics Industry: High Cleanliness + Antistatic Dual Core

Requirement: Must meet ISO Class 5 cleanroom standards to prevent metal ion and particulate contamination of chips/optoelectronic components.

Corresponding consumables: Antistatic wipers and cleanroom wipes (WIP-0609). These wipes utilize lint-free fibers and an antistatic coating to ensure zero fiber shedding and zero static particle absorption during wiping.

Suzhou Jujie's advantages: Its cleanrooms are built to ISO Class 5/6 standards and are NEBB-certified. The production environment directly meets the highest cleanliness requirements of the semiconductor industry, with product particle emission levels ≤ 0.1μm.

2. Biopharmaceutical Industry: Sterility and Low Endotoxins Key

Requirements: Preventing microbial and endotoxin contamination of pharmaceuticals and medical devices while maintaining compatibility with aseptic operating procedures.

Supply Options: Lens cleaning wipes and tub wipes, made of medical-grade non-woven fabric and sterilized packaging, with an endotoxin content of ≤0.1 EU/ml (compliant with USP <71>).

Suzhou Jujie Advantage: Equipped with a German-imported liquid particle counter, it accurately detects residual microorganisms in the wipes, ensuring that each batch of product meets sterility standards.

3. Precision Manufacturing Industry: Wear and Chemical Resistance

Requirements: Resistant to mechanical friction, oil/chemical residue, and maintaining a clean surface.

Supply Options: Jumbo rolls of industrial wipes and M-3 Bemcot wipers, made of high-density fiber and chemical-resistant coating, offer 30% increased wear resistance and are suitable for machine tools, molds, and other applications.

Suzhou Jujie Advantage: Imported Japanese laser cutting machines achieve "zero burrs" on the edges of consumables, preventing fiber shedding and contamination of precision components during wiping.

How to Select Cleanroom Consumables?

Selection must focus on three key factors: application requirements, product performance, and regulatory compliance. Suzhou Jujie Electron Co., Ltd. provides comprehensive, comprehensive service to help customers accurately select the right cleanroom consumables:

Step 1: Determine the cleanliness level of the application.

Refer to ISO 14644-1 to determine whether the application falls under ISO 5 (semiconductor), ISO 6 (photoelectric), or ISO 7 (general cleanroom).

Suzhou Jujie Tip: If the application involves electrostatically sensitive devices (such as circuit boards), prioritize anti-static consumables (such as anti-static wipers) with a surface resistance of ≤10⁹Ω to effectively conduct static electricity.

Step 2: Match the contaminant type

If the contaminant is particulate matter (e.g., dust), choose lint-free wipes/paper (e.g., WIP-0609 cleanroom wipes) with a fiber diameter ≤1μm to minimize secondary contamination.

If the contaminant is oil/chemical reagents, choose chemical-resistant wipes (e.g., barreled wipes) that are resistant to solvents like ethanol and acetone and leave no residue after wiping.

Step 3: Verify Product Compliance

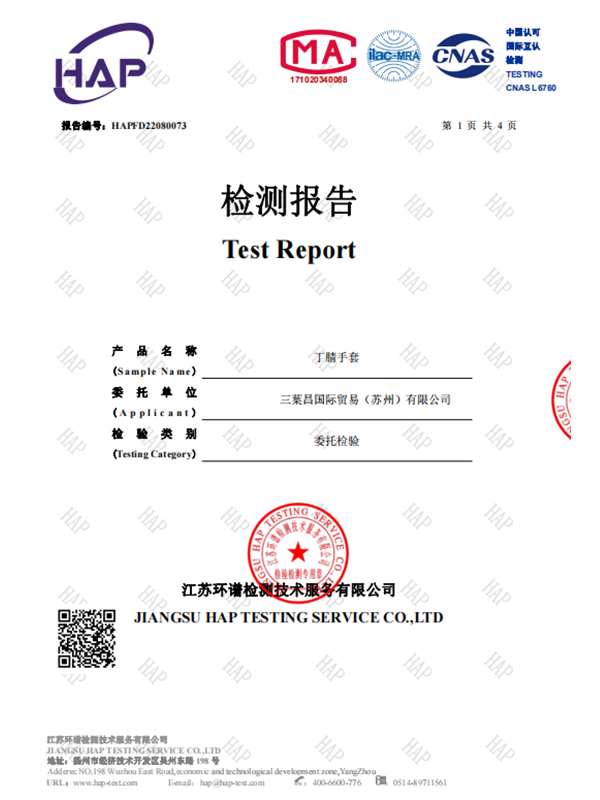

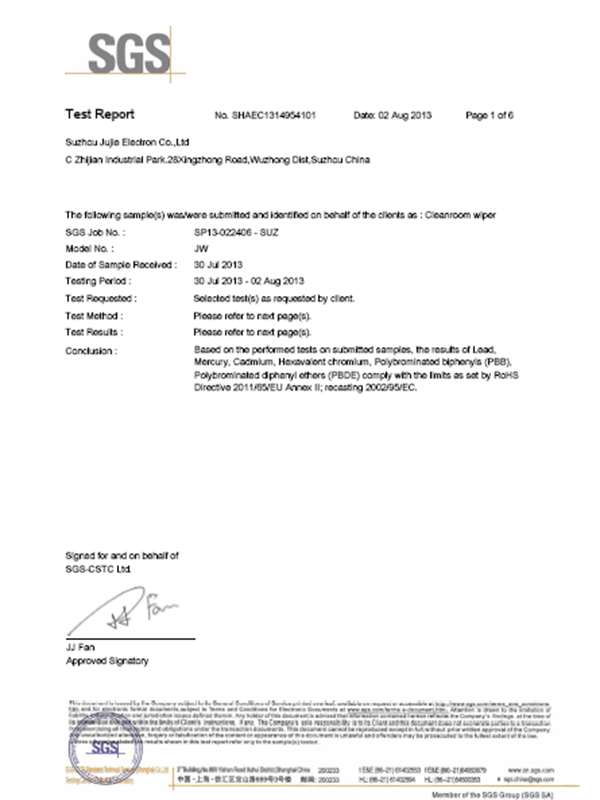

Check that the product has passed cleanroom industry certification. All consumables at Suzhou Jujie Electronics meet ISO Class 5/6 standards and provide third-party testing reports.

Confirm key parameters such as particle emission and anti-static performance. For example, the particle emission of anti-static wipers should be ≤10 particles/ft³. 4. Step 4: Consider Operational Ease

If frequent cleaning is required (e.g., on a production line), choose large rolls of industrial wipes (see "Large Roll Industrial Wipes" in the image). These can be used with a stand to reduce paper changes.

If precision cleaning is required (e.g., on a lens), choose pre-cut wipes (e.g., lens cleaning wipes) that are sized to fit the lens and minimize waste.

How did Suzhou Jujie Electronics become an industry benchmark?

Suzhou Jujie Electron Co., Ltd. has become a benchmark company in the cleanroom consumables industry by leveraging its three core strengths: "Technical Barriers + Production Capacity + Quality Control":

1. Technical Barriers: Full-chain Capabilities from Production to R&D

Leading Cleanroom Standards: The Shuyang factory, built in 2018, is built to ISO Class 5/6 cleanroom standards and is NEBB-certified. Its 8,000-square-meter lint-free workshop enables the production of high-end, lint-free, low-particle consumables.

Equipment and Technology Upgrades: 48 new automatic weaving/washing/setting production lines, equipped with imported Japanese laser and ultrasonic cutting machines, enable precise cutting of consumables without burrs, increasing the yield rate to 99.8%.

Strict Testing Technology: Equipped with German infrared spectrometers and American liquid particle counters, these facilities test key consumable indicators such as chemical composition, particle emission, and anti-static performance, ensuring consistent product consistency across each batch.

2. Capacity Advantage: Large-Scale Production Meets Global Demand

With a 33,000 m² plant and 48 production lines operating at full capacity, production capacity has increased tenfold compared to pre-2018 levels, enabling us to meet the volume demands of multiple industries, including semiconductors, biopharmaceuticals, and precision manufacturing.

Exports are projected to increase by 35% year-on-year in 2023, with products exported to Europe, the United States, Japan, South Korea, and other regions with developed cleanroom industries, making us a core supplier to globally renowned companies.

3. Quality Control: Full Traceability from Raw Materials to Delivery

Raw Material Traceability: We collaborate with international fiber brands such as Kanebo of Japan and DuPont of the United States to ensure lint-free and low-ion raw materials.

Production Traceability: Each batch of product is uniquely coded, tracing the raw material batch, production date, and test report. Customers can scan the code to access this information.

After-Sales Support: We offer free sample testing, technical support, and customized solutions. For example, we customized anti-static and chemical-resistant composite consumables for a semiconductor company to address the dual challenges of oil contamination and static electricity on their production lines.