If you need any help, please feel free to contact us

This is a critical question regarding health and safety. While many people are accustomed to using cotton swabs to clean their ear canals, not all cot...

View MoreBasic Properties of Nonwoven Wipes As a polymer material product, Nonwoven Wipes' basic properties determine their advantages in the cleaning process:...

View MoreIn ISO 5/6 standard cleanroom environments, Clean Swabs are a key tool for ensuring dust-free and fiber-free products. 1. No Fiber Shedding Clean Swab...

View MoreBest Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreWhat are the main applications of Antistatic products?

Antistatic products are core protective tools in cleanrooms and electronics manufacturing. Their application focuses on "static-sensitive environments," with their core value being to prevent static damage to precision components, equipment, or personnel.

1. Electronics and Semiconductor Industry

During chip manufacturing, packaging, and testing, static electricity can instantly disrupt micron-level circuits, rendering the product scrapped. Products such as anti-static bags and bottles are used to package chips and store electronic components, ensuring a static-free production process.

2. Pharmaceuticals and Biopharmaceuticals

Drug production requires a strictly clean environment, where static electricity can attract dust or contaminate liquid medicines. Products such as anti-static curtains and anti-static brushes are used in cleanroom environments to ensure drug purity and production safety.

3. Aerospace and Precision Instruments

Aerospace components (such as sensors and circuit boards) are extremely sensitive to static electricity. Products such as anti-static heel straps and anti-static replacement tweezers are used during assembly to prevent static discharge from damaging delicate structures.

4. Automotive Electronics and New Energy

New energy vehicle components, such as battery management systems and onboard chips, require Antistatic products to ensure consistent production. Suzhou Jujie Electronics Co., Ltd.'s Antistatic products cover the entire industry chain, meeting the needs of diverse scenarios.

What are the specifications of anti-static bags produced by Suzhou Jujie Electronics?

As a professional manufacturer of other Antistatic products, Suzhou Jujie Electronics Co., Ltd. offers a wide range of anti-static bag specifications, covering three dimensions: size, material, and function, to meet the needs of various industries.

1. Sizes and Specifications: From Micro Components to Large Equipment

Micro Bags: Suitable for packaging tiny components such as chips and resistors, with customizable sizes.

Medium Bags: Used for packaging circuit boards and small devices, with common sizes of 30cm x 40cm and 40cm x 50cm.

Large Bags: Suitable for packaging servers and industrial equipment, with sizes up to 100cm x 120cm and larger.

2. Material Selection: Considering both anti-static and protective properties

Transparent anti-static bags: Made of anti-static PE material, they offer excellent light transmittance, facilitating inspection of contents;

Opaque anti-static bags: Made of anti-static CPP or aluminum foil composite materials, they offer enhanced anti-static and moisture-proof properties;

Specialty bags: These include anti-static shielding bags for use in extreme static environments and anti-static flame-retardant bags for use in flammable environments.

3. Industry Customization: Meet the needs of specific applications

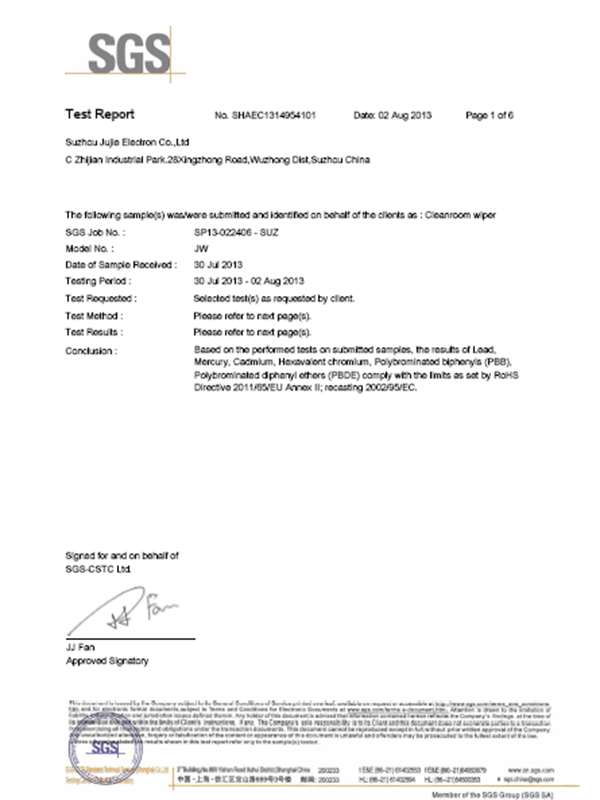

Semiconductor Industry: Bags are printed with ESD warning labels and comply with international standards such as IPC-A-610;

Pharmaceutical Industry: Bags are made of medical-grade materials and are ISO 13485 certified, ensuring drug safety;

Automotive Electronics: Bags are wear- and tear-resistant, suitable for high-frequency use on automated production lines.

What guarantees does Suzhou Jujie Electronics Co., Ltd.'s cleanroom standards provide for product quality?

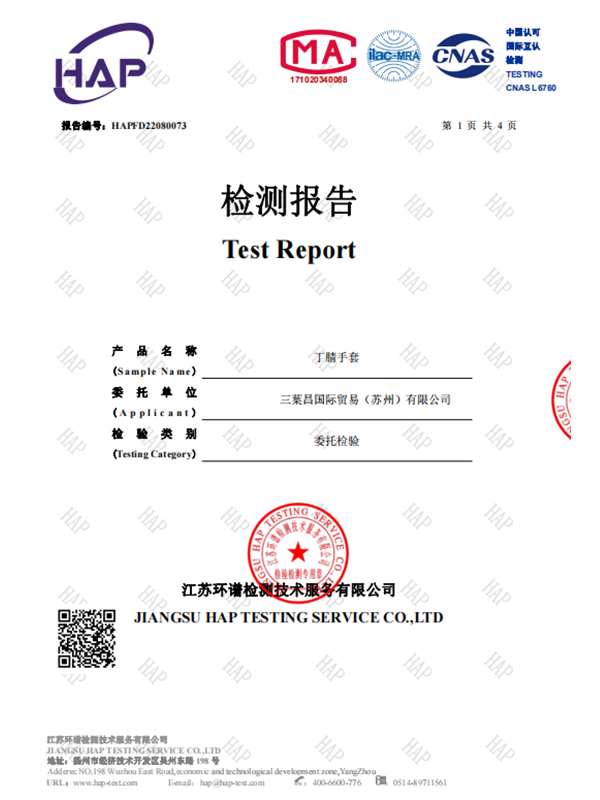

Suzhou Jujie Electron Co., Ltd. utilizes an ISO5/6 cleanroom as its core production environment. Through three key dimensions: hardware standards, testing systems, and production capacity support, we provide comprehensive quality assurance for our Other Antistatic Products products.

1. Hardware Standards: International Clean Environment

The cleanroom is built to ISO5 and ISO6 standards, with air cleanliness far exceeding industry standards.

NEBB-certified, its environmental stability and reliability reach top international standards.

The lint-free workshop is integrated with a fully automated production line to minimize interference from personnel and external contamination.

2. Testing System: Full-Process Quality Control

Equipped with imported Japanese laser cutting machines and ultrasonic cutting machines to ensure product dimensional accuracy.

High-end testing equipment such as infrared spectrometers and liquid particle counters imported from Germany, the United States, and South Korea comprehensively inspects raw materials and finished products for composition, cleanliness, and electrostatic performance.

Each batch of products undergoes anti-static performance testing, including surface resistivity and static decay time, to ensure compliance with international ESD standards.

3. Production Capacity and Stability: Scale Ensures Quality Consistency

Following an investment expansion in 2018, 48 new automated weaving, washing, and finishing production lines were added, increasing production capacity tenfold.

Large-scale production reduces unit costs while standardized processes ensure consistent quality across each batch.

The combination of a cleanroom environment and automated equipment reduces human error, ensuring industry-leading performance consistency in Antistatic products.