Development and innovation of cleanroom and anti-static product industry

Clean Mop:With the rapid development of high-tech industry and medical and health industry, the demand for cleanroom and related anti-static products is increasing. Suzhou Jujie Electron Co., Ltd. continuously improves its product quality and production capacity through investment expansion and technology upgrading to meet the market demand for high cleanliness and high-performance products.

Industry background

Cleanrooms are widely used in semiconductors, pharmaceuticals, biotechnology and medical fields, which have strict requirements on the cleanliness of the production environment. Cleanroom products not only need to have efficient cleaning capabilities, but also meet specific anti-static requirements to ensure the safety and reliability of the production process.

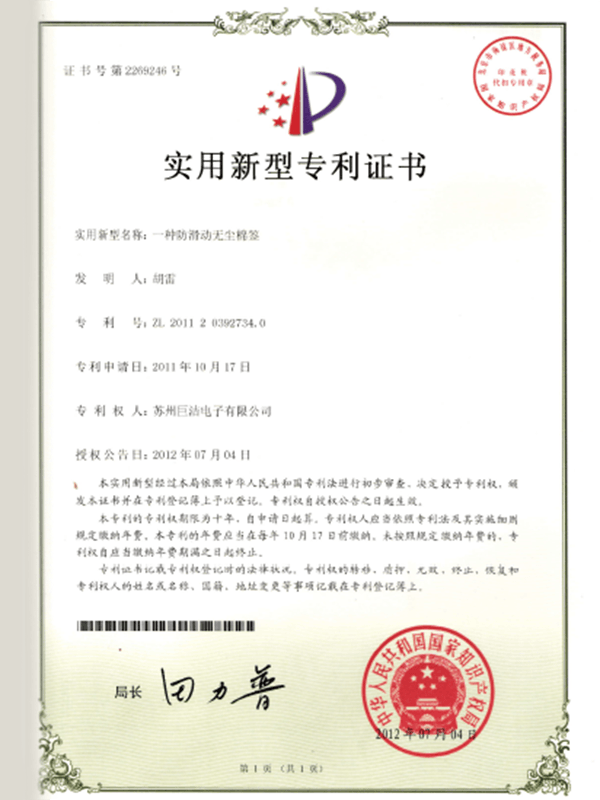

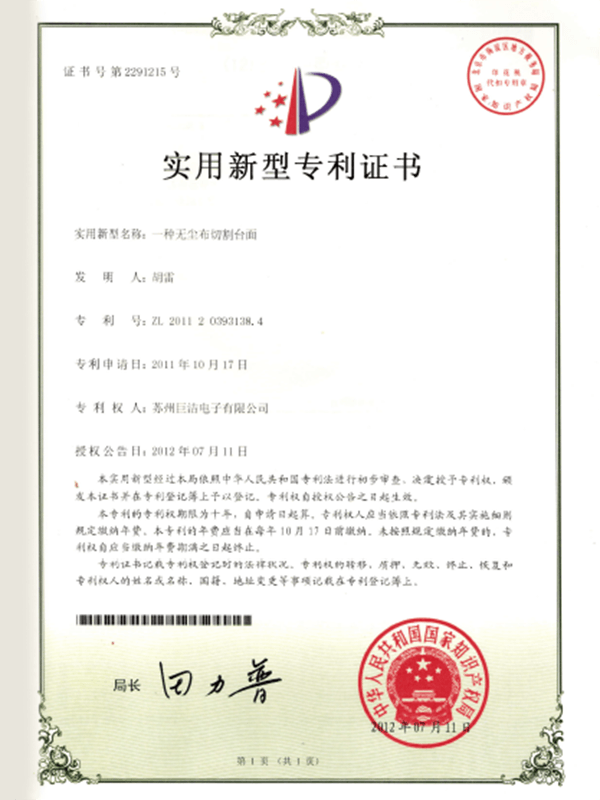

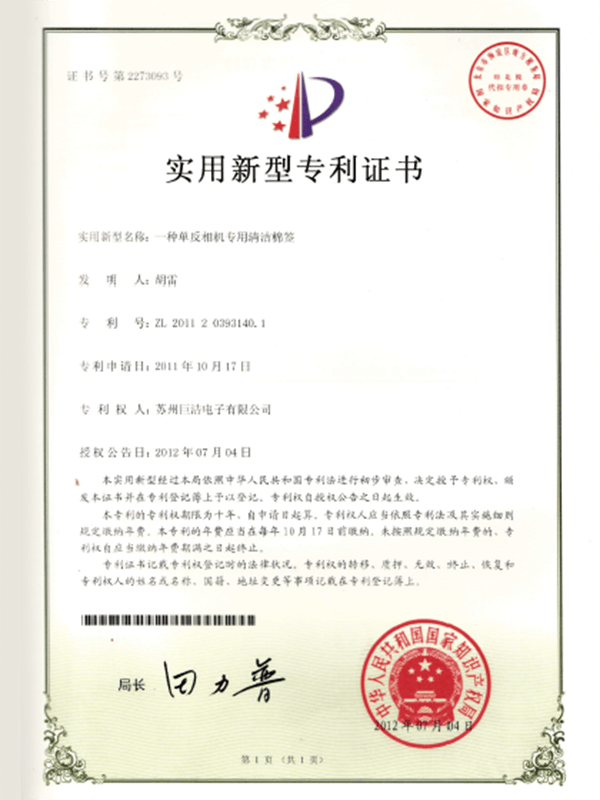

Technological innovation

Jujie Super Clean Technology has introduced laser cutting machines and ultrasonic cutting machines imported from Japan, as well as 48 fully automatic weaving, washing and shaping production lines. These equipment have greatly improved production efficiency and ensured high precision and consistency of products.

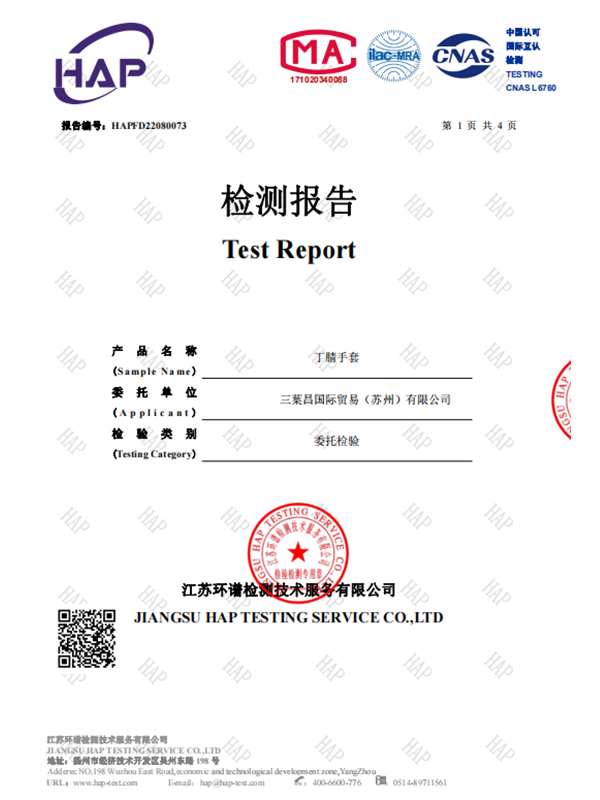

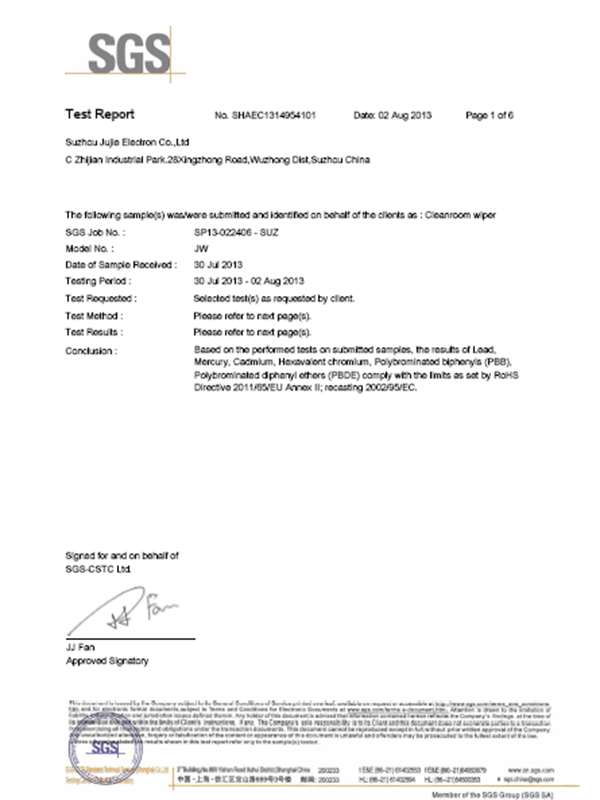

High-end testing equipment

The company uses infrared spectrometers and liquid particle counters imported from the United States, Germany and South Korea to ensure quality control of products during the manufacturing process. These equipment can accurately detect the number and size of particles in the product to ensure compliance with the strict requirements of ISO Class 5 and Class 6 standards.

Innovation in product design

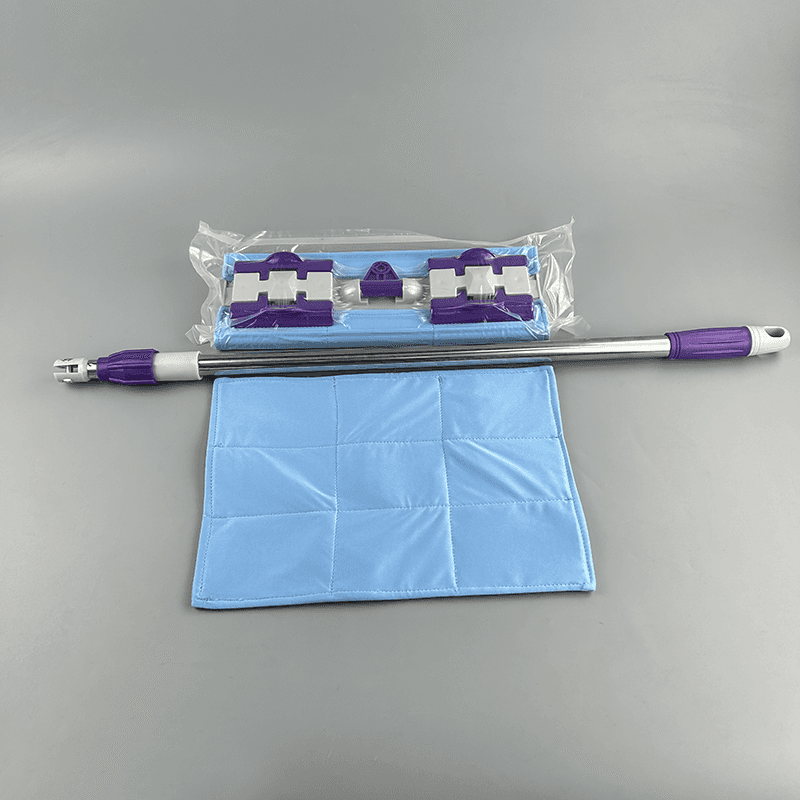

The cleaning mop is an innovative product launched by the company, designed for dust-free environments. Its features include good water absorption and decontamination capabilities, as well as easy cleaning, quick drying and durability. The lightweight design and 180° rotation function enable it to easily clean the dead corners of various dust-free workshops.

Product advantages

High performance of the cleaning mop

The cleaning mop is designed for dust-free industrial plants, medical laboratories and other environments. It not only has good water absorption and decontamination performance, but also can dry quickly to reduce the risk of secondary pollution. The lightweight design makes operation more convenient, the 180° rotation function ensures no dead corner cleaning, and the reinforced design ensures product durability.

Ease of use and convenience

The cloth cover design of the cleaning mop is easy to install, disassemble and replace, so that the cleaning effect can still be maintained in a high-frequency use environment. Its excellent design makes the operation more humane and suitable for various dust-free working environments.

Industry trends

Continuous growth of market demand

With the increasing demand for high-cleanliness environments in the electronics, medical and biotechnology industries, the market size of cleanroom and anti-static products continues to expand. In the future, the requirements for product precision and cleanliness will be more stringent, promoting continuous innovation in the industry.

Automation and intelligence

Automated production and intelligent management will become important trends in the development of the industry. Through the application of smart devices and Internet of Things technology, enterprises can optimize production processes and monitor product quality in real time.

Environmental protection and sustainable development

The global emphasis on environmental protection and sustainable development has prompted the industry to explore greener production materials and processes. In the future, green manufacturing and circular economy will become important directions for the development of the clean room and anti-static products industry.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français