If you need any help, please feel free to contact us

A stick roller is a cleaning tool that usually consists of a long handle and a roller with a sticky surface at one end. It is used to remove dust, hair, and small debris from clothing, furniture, carpets, and other surfaces. When in use, just roll the sticky roller on the surface that needs to be cleaned, and the sticky surface can absorb and carry away dirt. The adhesive roller is a convenient tool commonly used in household and commercial cleaning, easy to use and effective.

This is a critical question regarding health and safety. While many people are accustomed to using cotton swabs to clean their ear canals, not all cot...

View MoreBasic Properties of Nonwoven Wipes As a polymer material product, Nonwoven Wipes' basic properties determine their advantages in the cleaning process:...

View MoreIn ISO 5/6 standard cleanroom environments, Clean Swabs are a key tool for ensuring dust-free and fiber-free products. 1. No Fiber Shedding Clean Swab...

View MoreBest Operating Procedure for LCDs, OLEDs, and Optical Lenses 1. Preparation: Wear anti-static gloves and ensure your hands are dust-free. Use disposab...

View MoreWhat surfaces can a sticky roller clean?

The sticky roller's adhesive surface allows it to efficiently clean a variety of surfaces, covering both home and commercial cleaning needs:

Clothing and fabrics: Quickly absorbs dust, hair, and fiber debris from fabrics like clothing, curtains, and sofa covers, preventing damage that can occur with traditional vacuums.

Furniture and appliances: Suitable for smooth surfaces like wooden furniture, glass tabletops, and metal appliances, removing everyday dust and fingerprints.

Carpets and soft furnishings: Strongly absorbs fine debris from soft surfaces like carpets and floor mats, leaving no residue.

Electronic devices: Suitable for cleaning delicate devices like computer keyboards, mobile phone screens, and camera lenses. The sticky surface won't scratch the screen or leave water marks, making it a safe cleaning tool for electronic products.

How often should the sticky surface of a sticky roller be replaced?

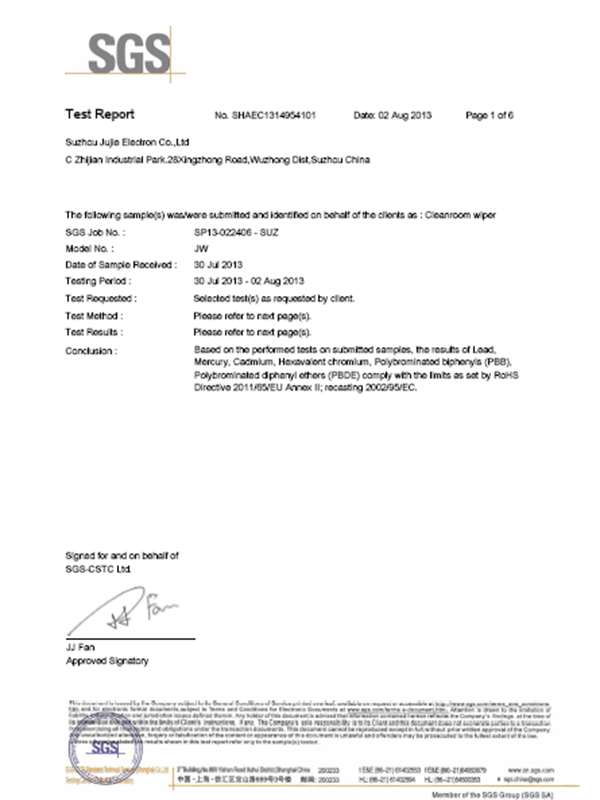

The replacement cycle for the sticky surface depends on the frequency of use and the intensity of cleaning. Suzhou Jujie Electronic Co., Ltd.'s products are designed with durability and practicality in mind:

Daily home use: If you clean 2-3 times a week, the sticky surface can last 1-2 months. When the stickiness of the surface decreases, such as when the adsorption capacity weakens and dust becomes less likely to adhere, the roller needs to be replaced.

High-frequency commercial use: In settings like hotels and hospitals where daily cleaning is required, the sticky surface may need to be replaced every 2-4 weeks to ensure cleaning efficiency.

Material differences: Suzhou Jujie's sticky rollers are made of high-quality sticky materials (such as silicone and PP film), which are more resistant to dirt and aging than ordinary products, extending their service life.

Easy replacement: Most products offer a "roller + replacement core" design, allowing users to purchase replacement cores separately, reducing long-term costs.

What types of sticky rollers does Suzhou Jujie Electronic Co., Ltd. offer?

As a professional sticky roller manufacturer, Suzhou Jujie Electronic Co., Ltd. Ltd., leveraging a 33,000-square-meter modern factory and 48 fully automated production lines, offers a wide range of sticky rollers suitable for various applications:

PP Sticky Rollers: Made of polypropylene (PP), they are lightweight, durable, and cost-effective for daily household cleaning.

Silicone Sticky Rollers:

All-Aluminum: Aluminum alloy frame with silicone surface offers high strength and excellent heat dissipation, making them suitable for industrial applications.

Black Aluminum: Black aluminum alloy with silicone offers stain resistance and a premium feel, making them ideal for cleaning high-end furniture.

Plastic: Plastic frame with silicone offers lightweight and easy portability, making them ideal for travel or cleaning small spaces.

ABS: ABS engineering plastic frame offers strong impact resistance, making them suitable for frequent use in commercial spaces.

Aluminum: Aluminum base with silicone provides excellent flatness, making them suitable for cleaning large surfaces such as glass and metal.

Multi-Roller Combination: These multi-roller designs, such as the "Stepped Sticky Roller," enhance cleaning efficiency and are ideal for cleaning large carpets or soft furnishings.

Customized Products: Leveraging high-end equipment such as imported Japanese laser cutting machines and German infrared spectrometers, we can customize sizes, materials, and functions to meet specific application needs.