Rubber Sticky Roller - Ideal for Efficient Cleaning

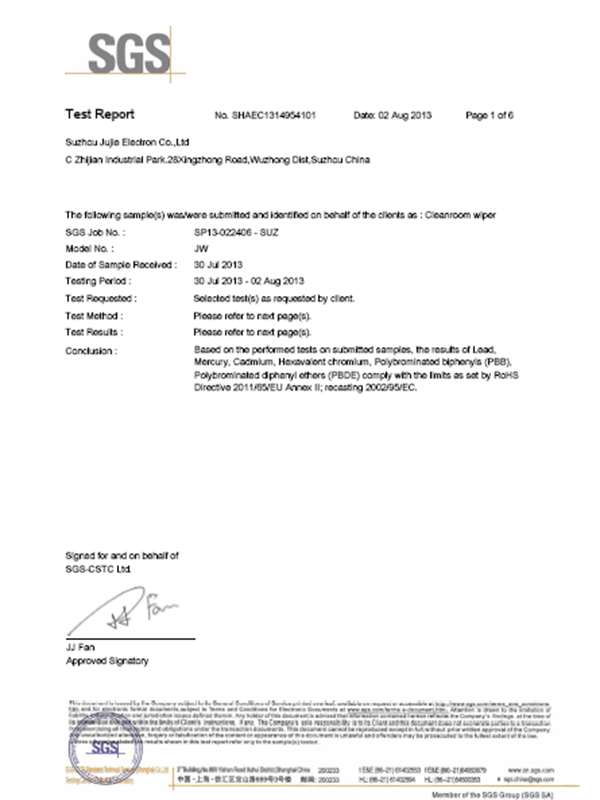

In environments with high precision and high cleanliness requirements, it is essential to keep equipment and surfaces clean. Suzhou Jujie Electron Co., Ltd. recommends our rubber sticky rollers, which are designed to meet various cleaning needs, especially in circuit boards, displays, printing equipment, clean rooms and electronics industries.

Product Features

High-quality silicone material: Our rubber sticky rollers are made of soft and highly viscous silicone material. Silicone has excellent elasticity and wear resistance, allowing the sticky roller to maintain its cleaning effect over long periods of use while being able to reach hard-to-reach areas.

Efficient cleaning ability: Compared with traditional sticky rollers, silicone sticky rollers can clean various surfaces faster and easier. It can effectively remove deep dust, lint and dirt in circuit boards, displays, printing equipment and clean rooms, ensuring high cleanliness of the environment.

Reaching into hard-to-reach areas: The soft nature of silicone allows the roller to adapt to irregular surfaces and reach into gaps and corners that are difficult for traditional rollers to reach. This makes it particularly good when dealing with complex equipment and delicate surfaces.

Wide range of applications: Whether in circuit board production, display maintenance, printing process or daily cleaning of clean rooms, our silicone sticky roller can exert its powerful cleaning ability. It is ideal for handling a variety of contaminants, helping to improve production efficiency and reduce scrap rates.

Customization service: According to the specific needs of our customers, we provide customization services, and can adjust the size and design of the roller according to your requirements. Whether it is for a specific application or a special environment, we can provide tailor-made solutions.

Application areas

Circuit boards and displays: In these high-precision fields, removing fine particles and dust from the surface is crucial to ensure product performance and quality. Silicone sticky rollers can effectively clean and reduce product defects.

Printing equipment: During the printing process, dust and dirt may affect the printing quality. Silicone sticky rollers can effectively remove these contaminants and keep the equipment in the best condition.

Clean room: For daily maintenance of clean rooms, silicone sticky rollers can effectively remove tiny contaminants, maintain the cleanliness standards of the environment, and ensure the smooth progress of the production process.

Electronics industry: In the production and maintenance of electronic products, it is crucial to keep the surface dust-free. Silicone sticky rollers can quickly clean all kinds of electronic components and ensure product stability and reliability.

Summary

Suzhou Jujie Electron Co., Ltd.'s rubber sticky roller is an ideal choice for efficient cleaning. With high-quality silicone material and excellent cleaning performance, it can provide excellent cleaning results in various applications. We also provide customized services to ensure that every customer can get the product that best suits their needs. Choose our silicone sticky roller to improve your cleaning efficiency and stabilize your production quality.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français