Introduction

LCD roll wiper is made of polyester or microfiber fiber through a special process knitted.

It is Ideal used in semiconductor Industry, LCD Industry and SMT.

Introduction

LCD roll wiper is made of polyester or microfiber fiber through a special process knitted.

It is Ideal used in semiconductor Industry, LCD Industry and SMT.

This is a critical question regarding health and safety. While many people are accustomed to using cotton swabs to clean their ear canals, not all cotton swabs are suitable for this purpose. Here's a ...

View MoreBasic Properties of Nonwoven Wipes As a polymer material product, Nonwoven Wipes' basic properties determine their advantages in the cleaning process: 1.High Absorbency Fiber Structure: The three-dime...

View MoreIn ISO 5/6 standard cleanroom environments, Clean Swabs are a key tool for ensuring dust-free and fiber-free products. 1. No Fiber Shedding Clean Swabs use a special polyester fiber material, which is...

View MoreProduct Recommendation: LCD Roll Wiper

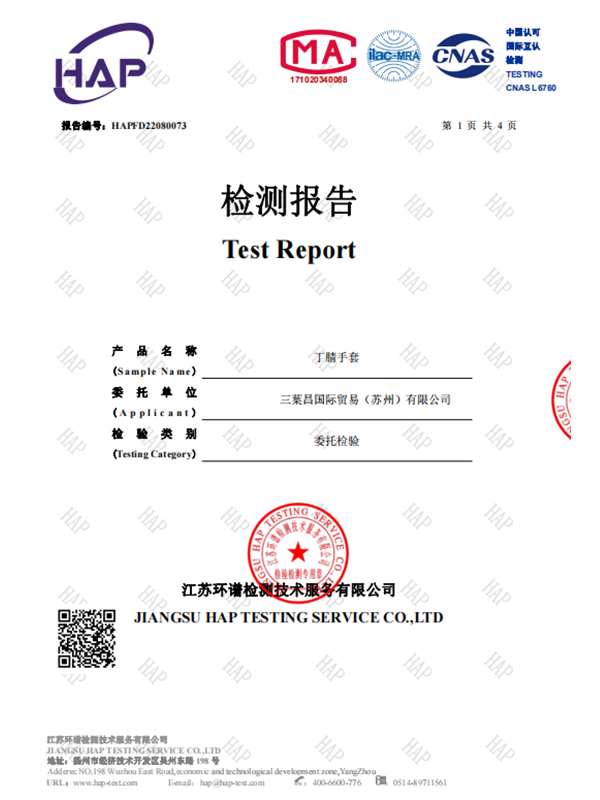

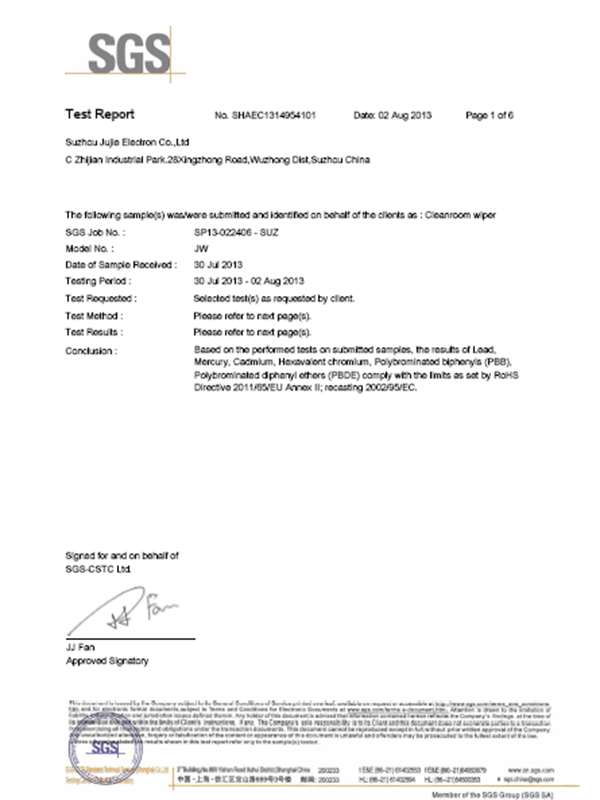

In clean environments and high-precision manufacturing processes, choosing the right wiping material is crucial. Since its establishment in 2005, Suzhou Jujie Electron Co., Ltd. has been focusing on the research and development and production of cleanroom and anti-static products. We are proud to launch LCD Roll Wipes, which are ideal for ensuring the cleaning needs of the semiconductor, LCD and SMT industries.

Product Introduction

LCD Roll Wipes are made of high-quality polyester or microfiber, woven through a special process, and have the following key features:

Efficient cleaning performance: The wipes have excellent cleaning ability and can effectively remove tiny particles, dust and dirt to ensure a smooth and traceless surface.

High-quality materials: The polyester and microfiber materials used are precisely processed to provide stronger adsorption capacity and lower particle release.

Roll design: The roll design is easy to use and store, ensuring that a fresh wipe surface is provided every time it is used, reducing the frequency of handling and replacement.

Wide applicability: Designed specifically for the semiconductor, LCD and SMT industries, it can meet high-demand cleaning standards and is suitable for a variety of production and testing environments.

Application Areas

LCD wipes are particularly suitable for the following industries:

Semiconductor industry: In the semiconductor manufacturing process, it is crucial to keep the environment dust-free. This wipe can effectively remove tiny particles generated during the production process to ensure product quality.

LCD industry: In the production and testing of LCD panels, this wipe can clean the surface of the display screen, remove dust and stains, and ensure the clarity and accuracy of the display effect.

SMT industry: In the surface mount technology (SMT) production process, wipes are used to clean circuit boards and equipment, reduce manufacturing defects, and improve product reliability.

Company Background

Suzhou Jujie Electron Co., Ltd. provides high-quality clean room and anti-static products to customers around the world with its professional R&D team and advanced production facilities. We have a modern factory of 33,000 square meters, equipped with fully automatic production lines and high-end testing equipment to ensure product quality and production efficiency. Our products are exported to 83 countries and regions, and have been recognized by global well-known companies such as Apple, Huawei, and Samsung.

Customized Service

We provide customized services for LCD wipes, including different sizes and specifications to meet your specific needs. Whether it is an OEM or ODM order, we can provide tailor-made solutions according to your requirements.

Conclusion

LCD wipes are the preferred cleaning tool in the semiconductor, LCD and SMT industries for their excellent cleaning performance and high-quality materials. If you need an efficient and reliable wipe, LCD wipes will be your best choice. Welcome to contact us for more information, we look forward to working with you to improve your cleaning standards and production efficiency.