Professional Stainless Steel Tweezers to help the electronics industry with precision operations

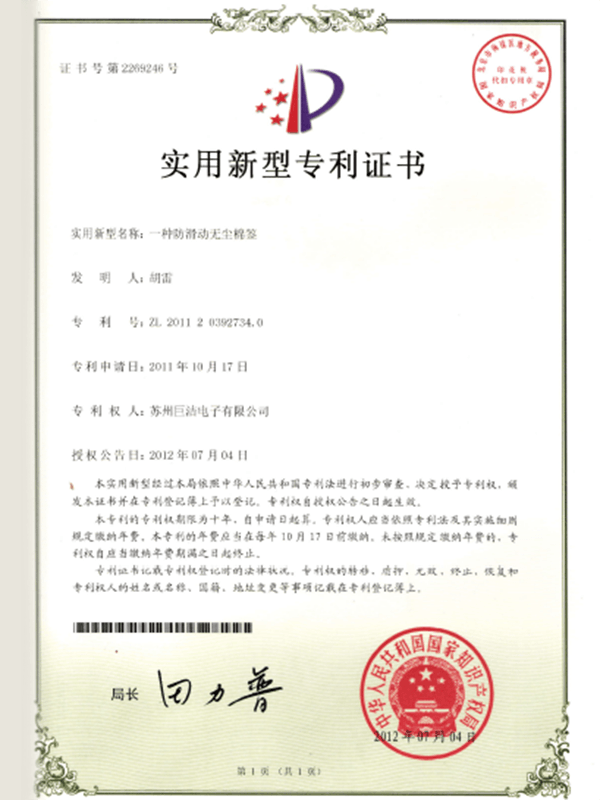

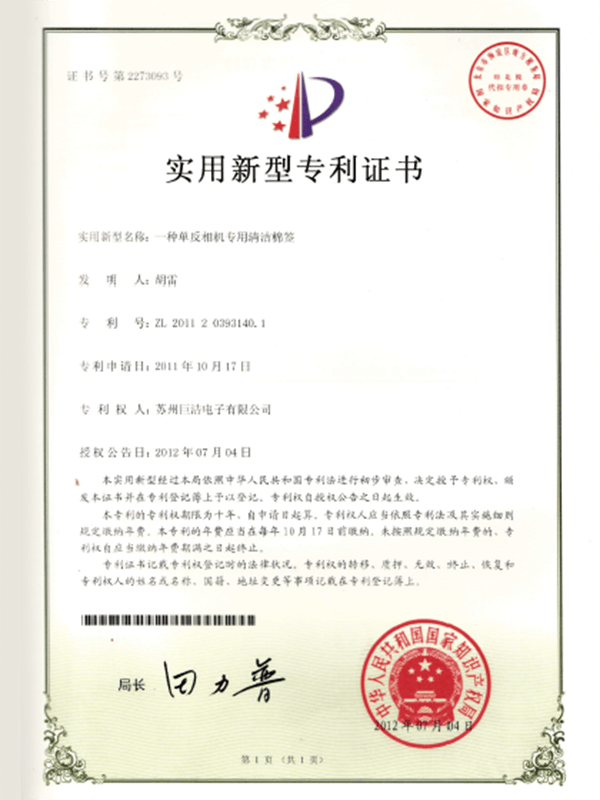

In the electronics industry, every tiny component is crucial, and the tools used to operate these components need to be precise and professional. Suzhou Jujie Electron Co., Ltd., as a high-tech enterprise with 16 years of professional experience, is committed to providing high-quality clean rooms and anti-static products to meet the needs of the global electronics industry.

Corporate Strength

Since its establishment in 2005, Suzhou Jujie Electron Co., Ltd. has continuously expanded and improved its R&D and production capabilities. In 2018, the company invested in Jujie Super Clean Technology Shuyang Co., Ltd. and expanded its plant by 33,000 square meters, including 8,000 square meters of dust-free workshops. Our clean rooms are strictly built in accordance with ISO Class 5 and Class 6 standards and are NEBB certified, ensuring the high standards and quality of our products.

Advanced equipment

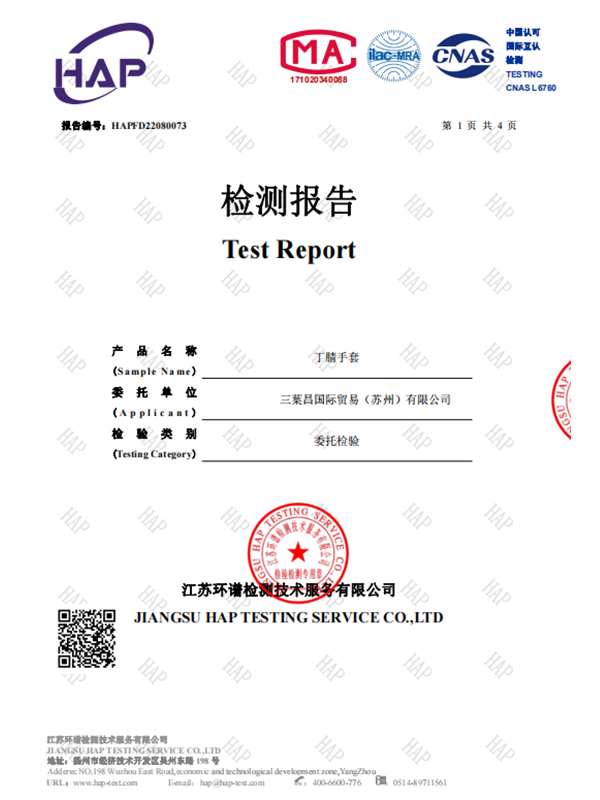

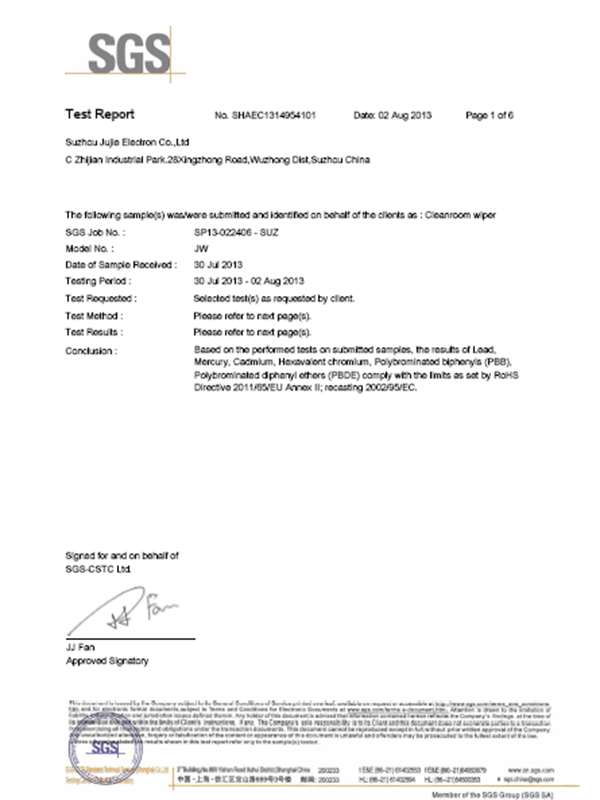

We have introduced 48 fully automatic weaving, washing and shaping production lines, equipped with high-end production equipment such as laser cutting machines and ultrasonic cutting machines imported from Japan, as well as infrared spectrometers, liquid particle counters and other testing equipment imported from Germany, the United States and South Korea. The production capacity has increased by 10 times, ensuring the accuracy and reliability of the products.

International cooperation

Suzhou Jujie has a professional foreign trade sales team and independent import and export rights. It has established cooperative relations with more than 30 Fortune 500 companies around the world, and its products are exported to 83 countries and regions. Our products have been recognized by well-known companies such as Apple, Huawei, and Samsung, and are also the sales agent of Kimberly Clark products.

Product recommendation

Today, we especially recommend a series of anti-static tweezers, which are made of high-quality stainless steel and have acid resistance, non-magnetic, chemical corrosion resistance, heat resistance and other characteristics. They are ideal for precision operations in the electronics industry:

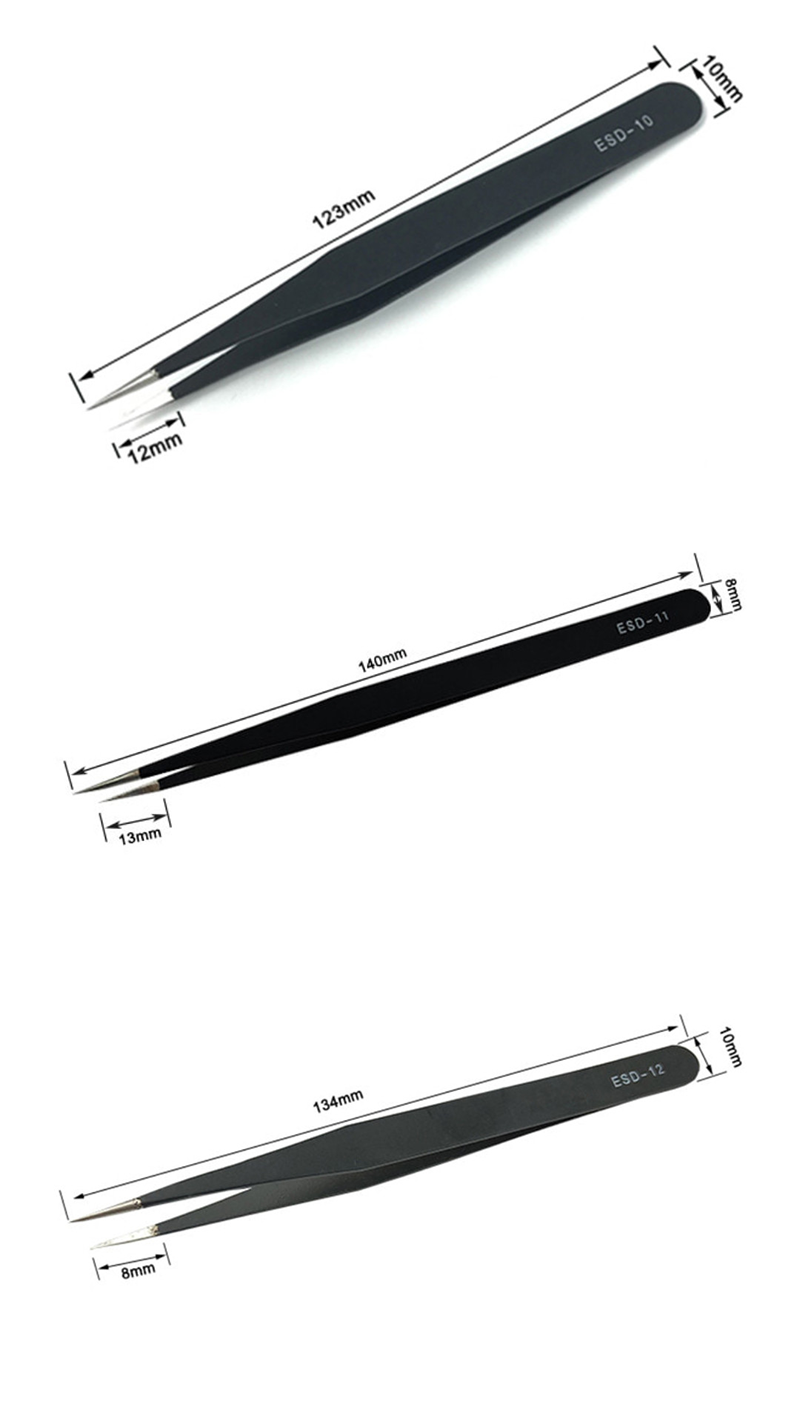

1. ESD-10 (standard): Designed for welding integrated circuit chips, installing or replacing parts, providing a stable and precise operating experience.

2. ESD-11 (large): The tip is longer, suitable for fine operations in precision electronic components.

3. ESD-12 (high elasticity): The tip is firm and will not bend even when clamping the circuit board strongly, ensuring the safety of the parts.

4. ESD-13 (round): The round tip design avoids component damage and is suitable for extracting chip circuits.

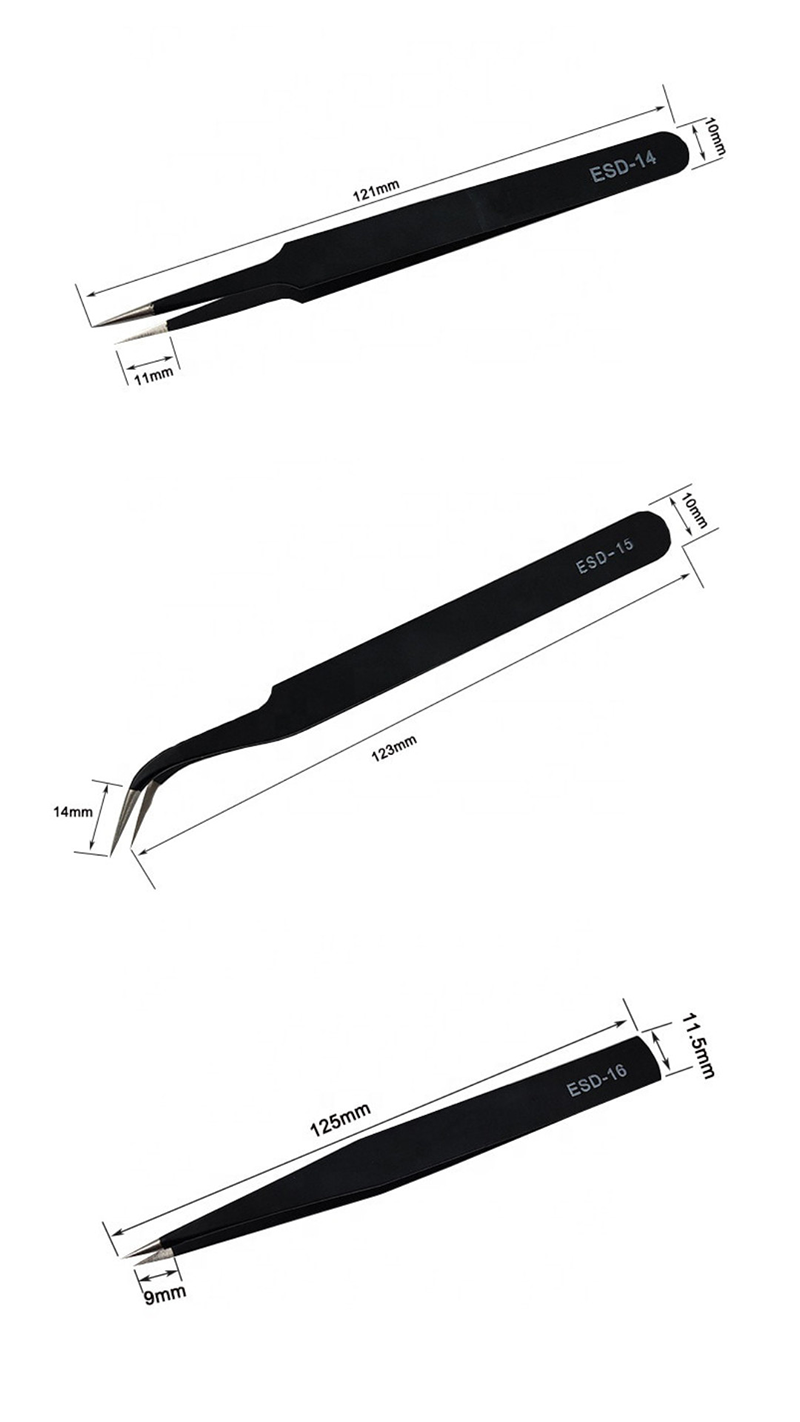

5. ESD-14 (extra fine): The tip is extra fine and sharp, suitable for delicate operations in high-density integrated circuit chips.

6. ESD-15 (eagle beak): The tip is bent 450°, especially suitable for extracting parts in narrow spaces.

Customer First

We adhere to the concept of "people-oriented, quality-leading, customer-oriented, and pursuit of excellence". With a strong R&D team and rich experience accumulated over the years, we can undertake OEM and ODM orders according to customer requirements to meet the special needs of different customers.

Choose Suzhou Jujie, choose professionalism and trust. We look forward to working with you to create a better future.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français