Excellent cleaning effect of DCR pad: ideal choice for improving the performance of silicone sticky rollers

Company Background

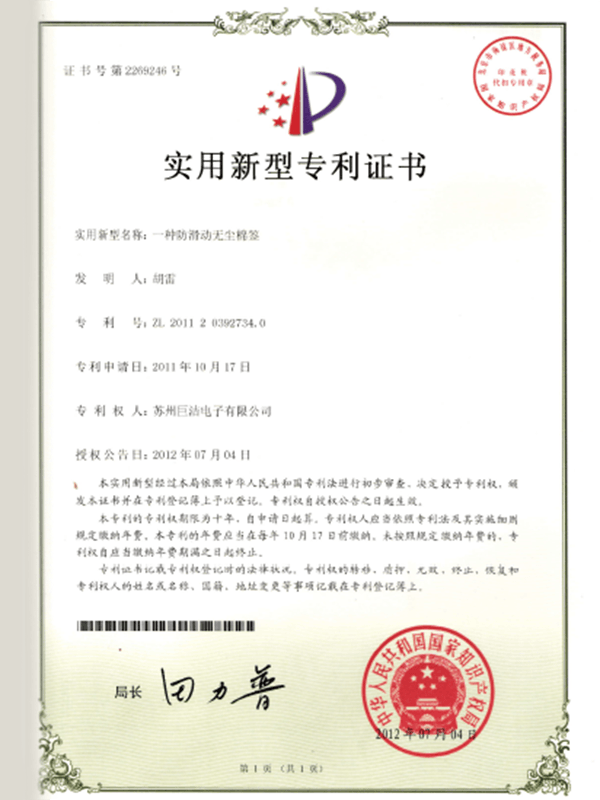

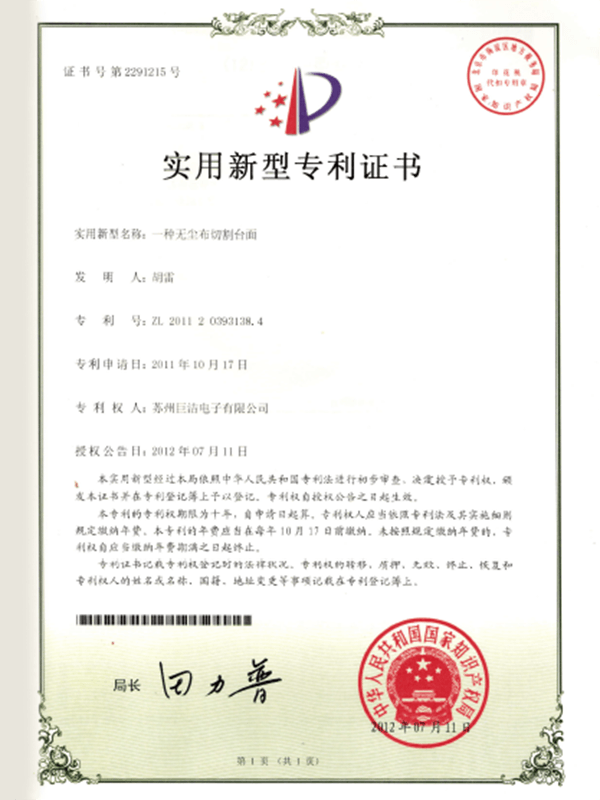

Suzhou Jujie Electron Co., Ltd., since its establishment in 2005, has been committed to the research and development, production, sales and service of clean room and anti-static products. Our factory area reaches 33,000 square meters, including 8,000 square meters of lint-free workshop. The clean room meets ISO Class 5 and Class 6 standards and has obtained NEBB certification. By introducing advanced fully automatic production lines and high-end testing equipment, our production capacity has increased 10 times. The company has a professional foreign trade sales team and independent import and export rights. Our products are exported to 83 countries and regions and cooperate with many Fortune 500 companies. We are committed to providing high-quality anti-static products, supporting OEM and ODM orders, adhering to the concept of "people-oriented, quality-leading, customer-first, and pursuit of excellence".

Product advantages of DCR pads

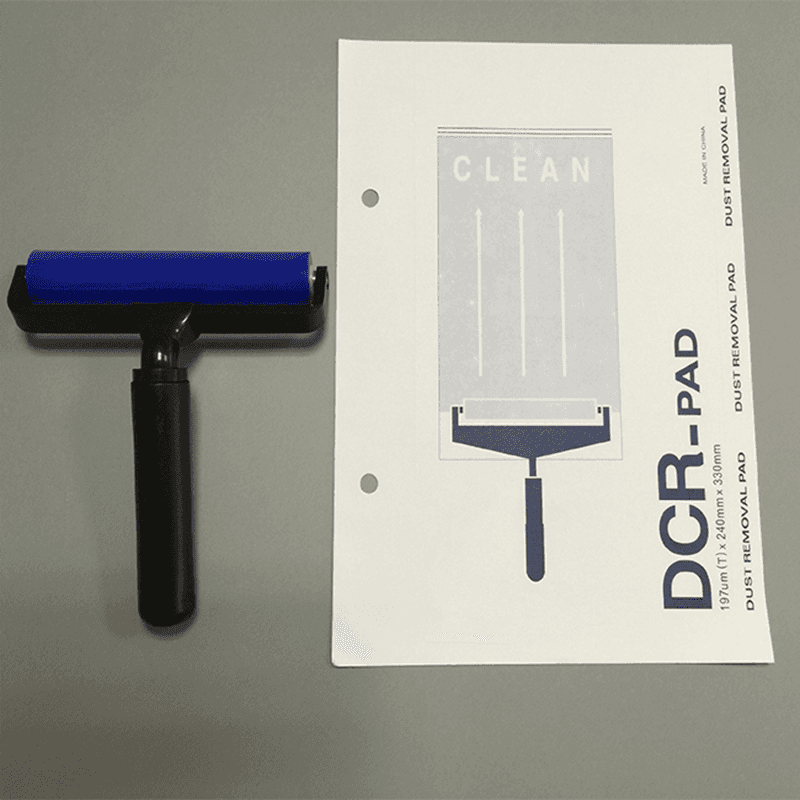

1. Efficient cleaning

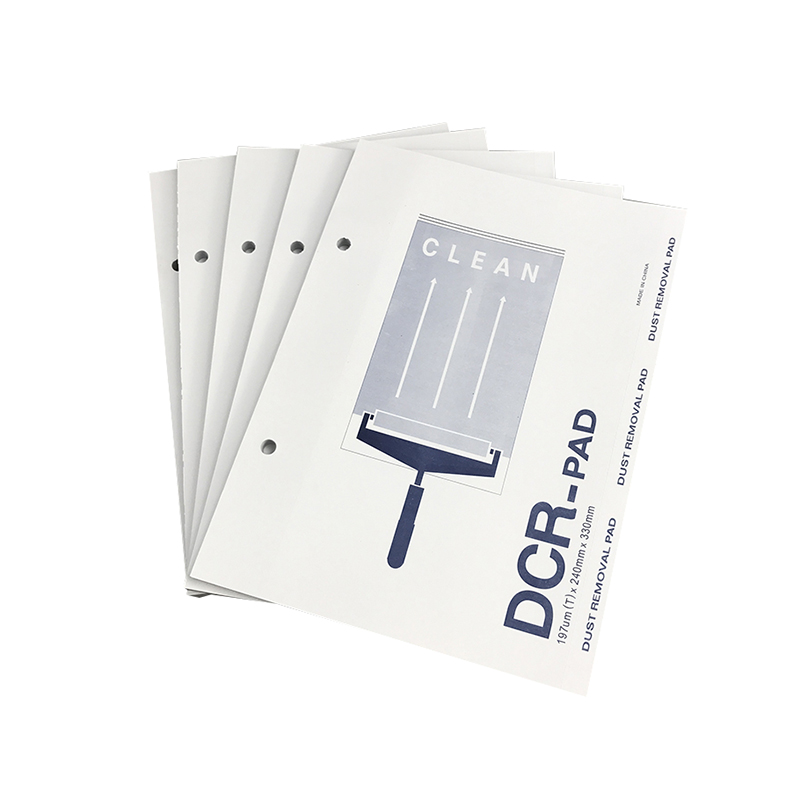

DCR pads are specially designed for cleaning silicone sticky rollers and provide an efficient cleaning solution. When using, just tear off the protective paper on the DCR pad and push the silicone sticky roller on the DCR pad in one direction to transfer the dust and impurities attached to the sticky roller to the DCR pad. This method can effectively remove pollutants on the surface of the sticky roller, restore its optimal dust removal effect, and ensure the cleanliness of the production environment.

2. Maintaining excellent dust removal effect

Regularly using the DCR pad to clean the silicone sticky roller can effectively maintain the dust removal performance of the sticky roller. When the glue layer on the DCR pad becomes dirty and the viscosity decreases, replace the next layer of DCR pad in time to ensure continuous and efficient dust removal effect. In this way, users can ensure that the silicone sticky roller always maintains a good working condition throughout the working cycle to avoid affecting production quality due to the decline in sticky roller performance.

3. Low maintenance cost

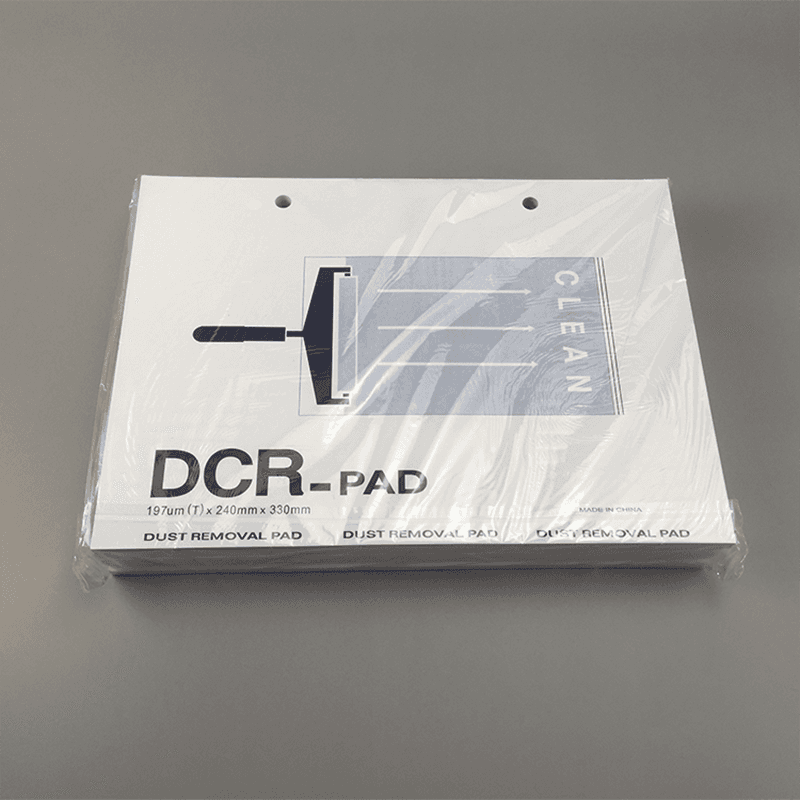

The design of the DCR pad makes the cleaning process simple and efficient. Due to its replaceable glue layer design, users only need to regularly replace one layer of the DCR pad before continuing to use it. Such a design not only reduces maintenance costs, but also improves the convenience of operation. Users do not need to perform complex cleaning on the entire sticky roller, and can complete the cleaning task with just the DCR pad, saving time and labor costs.

4. Easy operation

The use of the DCR pad is very intuitive and easy. Users only need to push the sticky roller on the DCR pad in sequence to complete the cleaning operation without additional tools or complicated steps. This design is suitable for various working environments, including laboratories, manufacturing workshops and other places that require high cleanliness.

5. Environmental protection and safety

The material selection of the DCR pad meets environmental protection standards, is non-toxic and odorless, and ensures safety during use. Users do not have to worry about the release of harmful substances during the cleaning operation, which ensures the health of operators and the cleanliness of the environment.

Summary

As an effective tool for cleaning silicone sticky rollers, the DCR pad provides an ideal solution with its efficient cleaning ability, low maintenance cost and simple operation process. Suzhou Jujie Electron Co., Ltd., with its strong R&D and production capabilities, provides customers with high-quality DCR pads to help companies improve production efficiency and reduce operating costs. We always adhere to the concept of "people-oriented, quality-leading, customer first, pursuit of excellence" to provide customers with the best quality products and services.

中文简体

中文简体 English

English Español

Español русский

русский Deutsch

Deutsch Français

Français